For a sustainable finish of the facade, the construction needs to comply with the following conditions:

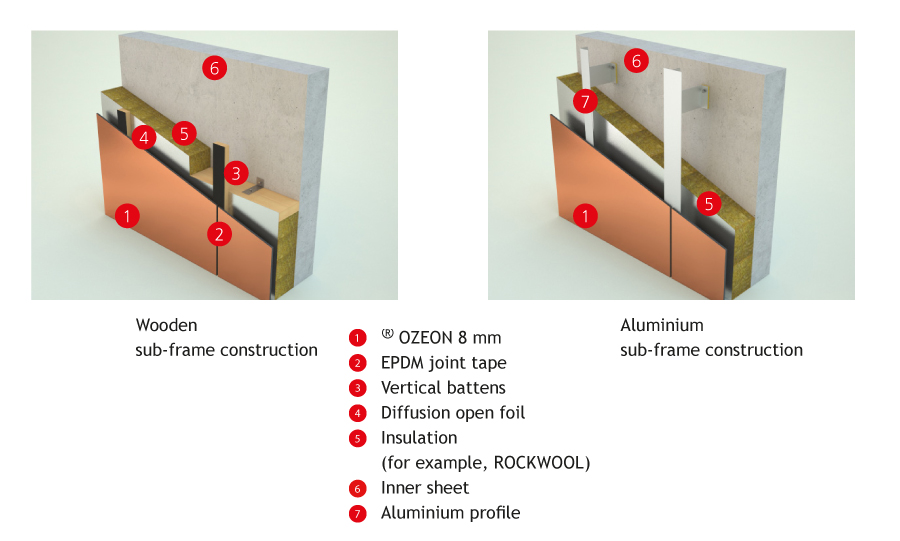

Conditions of a timber sub-frame construction:

- Mounting on vertical lines that meet sustainability class I or II according to NEN 5461 or to sustainability class III or IV, where the timber must be preserved in accordance with BRL0601.

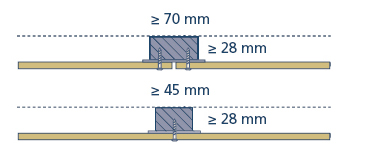

- At mechanical fixation the battens must have a width of least 70 mm at the seams of the plate and at least 45 mm at the in-between support; thickness has to be at least 28 mm.

- Process weatherproof joint tape at the seams to protect the timber sub-frame against weather influences.

Conditions of aluminium sub frame construction:

- The quality of the aluminium framework and the applied profiles should be F25, in accordance with DIN 1748. The quality of the STAINLESS STEEL connections must be in accordance with art. 7.2 of NEN 6710.

Ventilated constructions

With these type of facades, the outdoor facade will be constructed as a cavity wall with an indoor and outdoor layer, whereby a ventilated space is created between the cladding and insulation. Two versions are possible: the open and closed version.

Open facade

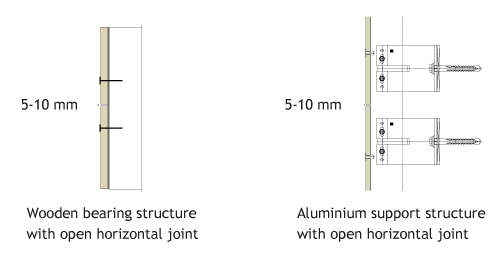

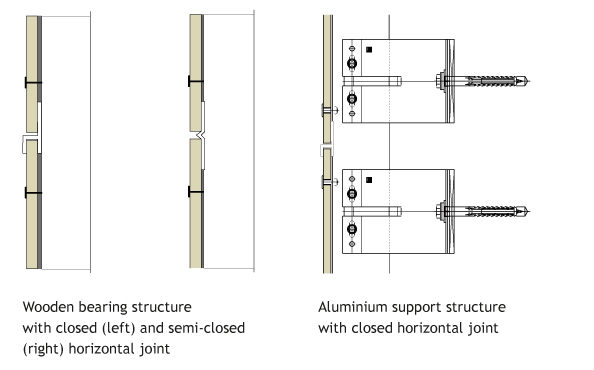

Horizontal joints

At an open version of the construction, the horizontal joints will be open with a seam of at least 5 mm and up to 10 mm.

At open joints on a wooden support structure the construction behind the vertical lines must be finished with a vapour permeable, water-repellent foil, that has no capillary action and is UV-resistant. The recommended space between vapour permeable, water repellent foil and OZEON ® is at least 20 mm but in practice usually holds the thickness of the framework (28 mm or 34 mm). This is to drain rainwater.

For an aluminum support structure OZEON ® recommends a cavity depth of at least 40 mm and no more than 100 mm, where the insulation should be in accordance with NEN-EN 13162. The insulation material must be moisture resistant and not degenerate by UV radiation.

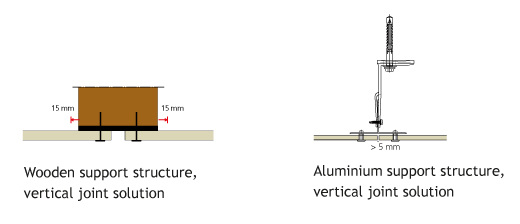

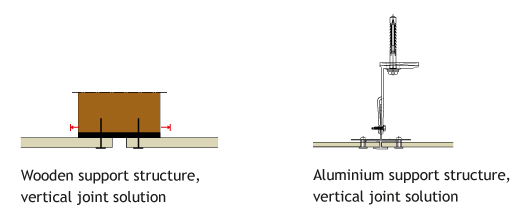

Vertical joints

The vertical joints between the panels are closed for wind and rain but show a mounting joint. The panels can, under conditions, be mounted seamlessly where appropriate.

- No movements in the sub-construction

- Maximum length 15 m1

- Timber sub-frame construction with vertical battens

- Joint tape at the height of the seams

- Takes into account possible dilatations in the design

For the lifetime of wood vertical battens must be protected from rain water as much as possible. This can be done with a UV- and weather-resistant foamtape that is 15 mm wider on both sides than the framework. At a closed joint the joint does not need to protrude. It can also be done with an OZEON®Strip.

Closed facade

Horizontal joints

At a closed version of the facade construction, the horizontal joints will be closed by a profile, usually with a chair- or nose profile (semi-closed). Rain water is drained as much as possible on the outside of the cladding.

The sub-frame construction must be ventilated with ventilation-openings of at least 1000 mm2/m1 at the top- and bottom of the facade. The recommended cavity depth for a ventilated cavity is at least 20 mm, but has in practice usually the thickness of the frame work.

Vertical joints

The vertical joints between the panels are closed for wind and rain but do show a mounting joint. It’s possible to mount the panels seamlessly. For the lifetime of wood, the vertical battens must be protected from rainwater as much as possible. This is possible with UV-and weather-resistant joint tape. With a closed joint, the joint tape does not need to protrude. It can also be done with a strip OZEON®.

Mechanical on aluminium

Mechanical on aluminium

Blind rivets with flat head Ø 14 mm, stainless steel number 1.4567/ 1.4578 according EN 10088

Size 5 x 16/18 mm

Material number nail 1.4541 (EN 10088)

Upon fixation of OZEON® on an aluminium sub-frame construction, fixed and sliding fixation points must be used. Fixed anchorages can be drilled with Ø 5.2 mm and sliding fixation points must be drilled Ø 8 mm. The sliding fixation should be tightened with blind rivet pliers with a top unit (spacer) in order for the fixation can to move well.

Joints and Panel connections

OZEON® sheet material is very solid. It’s hardly sensitive to humidity and changes in temperature. Thus, the product can be applied seamlessly under certain conditions:

- Only for applications around the roof, such as gutter, fascia boards and eaves finishes

- Up to a maximum length of 15 metres

- In case of a timber sub-frame construction with vertical frame work where no movement of the sub-frame construction can occur

- At the height of the seams joint tape should be applied on the sub-frame construction to protect timber backing.

- It perpetuates the construction expansion joints with the OZEON® plate

At standard joint- and panel connections keep the following things in mind:

- Make sure to apply a seam of at least 5 mm in panel connections so that sufficient drainage can occur.

- OZEON® has a good dimension-stability, therefore keep in mind the difference in movement of other materials such as aluminium.

- At detailing joints, take into account the panel-, assembly- and construction tolerances.

- Process at the height of the seams joint tape on the sub-frame construction to protect the timber backing against weather influences.